-

Process for High-Sulfur Chalcopyrite Ores

Process for High-Sulfur Chalcopyrite OresThis low-cost, high-recovery process for the treatment of high-sulfur chalcopyrite ores includes the following stages:

1、Boiling Roasting;

2、Low-acid Leaching;

3、Flotation;

4、High-copper Leaching;

5、Copper Solvent Extraction;

6、Low-copper Solvent Extraction;

The process involves boiling roasting of high-sulfur chalcopyrite ores, followed by low-acid leaching and flotation without the need for additional reagents beyond a small amount of floatation agents. This method achieves over 85% sulfation rates for cobalt and copper, with extraction rates exceeding 98%, while the slag contains less than 0.15% cobalt and less than 0.30% copper. The roasting process is self-sustaining and requires no external energy input, resulting in low energy costs. Additionally, the steam generated during roasting can be utilized for heating in wet leaching, and the process avoids the addition of harmful elements like chlorine, thus minimizing the risk of corrosion to equipment and degradation of copper solvents.

-

Improving Flotation Indices of Chalcopyrite Ores

Improving Flotation Indices of Chalcopyrite OresImproving Flotation Indices of Chalcopyrite Ores for Gold Mining

This flotation method is designed to enhance the recovery and efficiency of gold mining by improving the flotation indices of chalcopyrite ores. The process is based on a specific flotation technique known as "Sulfide Leaching of Sulfur Salts - Sulfide Precipitation - Dihydrogen Water + Starch Coupled Inhibition - Copper Sulfide Selective Flotation Separation."

The method involves the following stages:

Coarse Flotation (Stage 1)

Scanning Flotation I (Stage 2)

Fine Flotation I (Stage 3)

Scanning Flotation II (Stage 4)

Fine Flotation II (Stage 5)

Fine Flotation III (Stage 6)

This flotation method enables the conversion of gold-bearing chalcopyrite ores into independent sulfide mineral forms, thereby preventing the loss of gold contained in chalcopyrite to tailings and optimizing the performance of combined inhibitors. It significantly improves the quality and recovery rates of precious metals such as gold and copper, ensuring sustainable, efficient, and environmentally friendly development of chalcopyrite ores with minimal alkalinity.

-

How copper is extracted from its ore

How copper is extracted from its oreSolid-Liquid-Solid Wetting Furnace Process for Dissolution of Chalcopyrite or Concentrate:

The process operates under conditions of over-saturation with water and/or non-hydrated salts. It intentionally and repeatedly applies wetting and drying steps to enhance chemical and physical phenomena on or in the mineral or concentrate, thereby inducing copper crystallization, re-crystallization, and liberation during the non-redox decomposition of sulfides and their subsequent reaction with chlorides.

This method comprises three steps: (a) Wetting, (b) Drying and Over-saturation, and (c) Cleaning and Re-wetting. These steps are performed under temperatures in the range of 20-40°C without considering redox potentials, while minimizing water and acid consumption, with no need for oxygen addition.

The process minimizes water and acid usage because sulfide transformation can occur solely in the presence of hydrated salts or with a small amount of added acid and water. Additionally, it allows reduced water use during agglomeration and/or solidification steps because water molecules from the hydrated salt wet the mineral, minimizing the amount of water required to be added during wetting and agglomeration/solidification.

This method can also be applied to sulfides of less noble metals such as nickel, zinc, cobalt, lead, and molybdenum, regardless of whether arsenic is present in the sulfide mineral matrix.

-

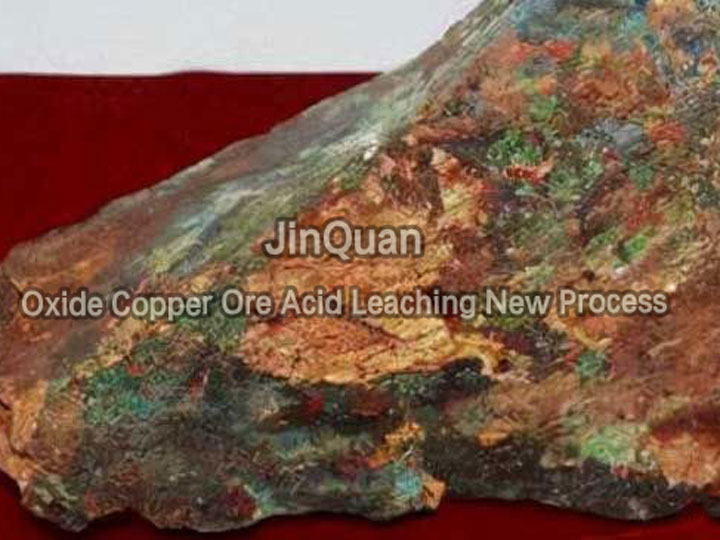

Oxide Copper Ore Acid Leaching New Process

Oxide Copper Ore Acid Leaching New ProcessOxide Copper Ore Acid Leaching New Process

Following the crushing and screening of copper oxide ores, the oversize material undergoes conventional acid leaching. The undersize material is subjected to concentration, thickening, and pelletizing before being used for further heap leaching.

The pregnant leach solution rich in copper ions undergoes solvent extraction and electrorefining to produce marketable cathode copper.

After concentration of the undersized material, a binder is added to create slurry. This slurry is then mixed with preprepared 5mm-25mm diameter acid-resistant crushed stones to form pellets. The pelletizing heap leaching process involves building heaps approximately 3-5 meters in height. During leaching, the sulfuric acid concentration ranges from 0.1-2 mol/L, and the leaching cycle typically lasts for 1-2 months.

This method is particularly suited for copper ores dominated by oxide copper in areas such as remote regions of Western China, especially in high-altitude areas where copper ore processing is challenging.

-

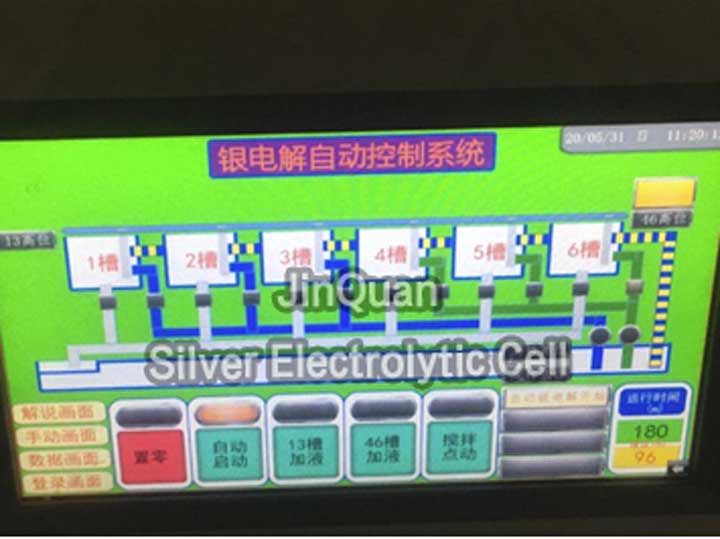

Automated Silver Electrolytic Cell

Automated Silver Electrolytic CellAutomated Silver Electrolytic Cell

1、Touch Screen: The unit is equipped with a touch screen that displays and controls the operation of the electrolytic tank's stirring, recirculation pump, rectifier power supply, and circulating bath liquid levels. It also tracks the operating time of the electrolytic tank and sequences the steps using a PLC to ensure they are executed in order. The output bin requires manual preparation of the anode plates on the rack beforehand via a mounting rail located below the smoke hood. Human assistance is needed for precise positioning of the anode plates. Silver powder must be manually scooped out.

2、Operation Console: The console displays various parameters such as voltages, total voltage, currents, statuses of pipe fittings, and operation status of the silver powder washing pump.

3、Liquid Level Monitoring and Alarms Between Storage Tanks: The system monitors and alerts on liquid levels between storage tanks during the transfer process.

-

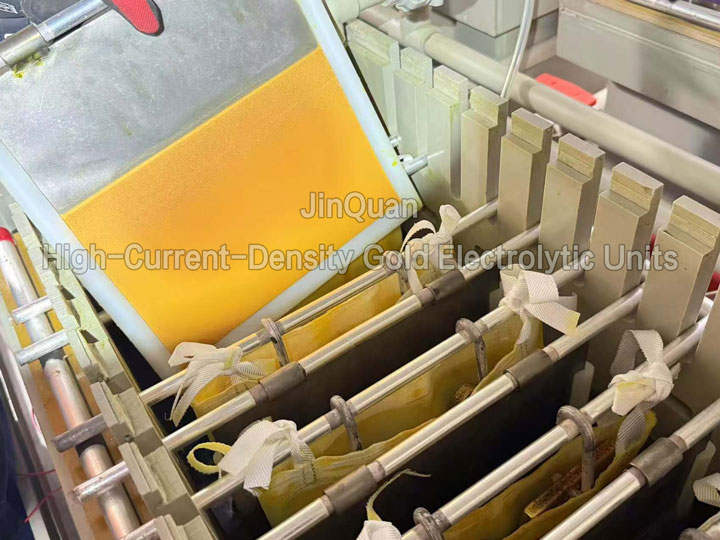

New Gold Electrolytic Refining Cell

New Gold Electrolytic Refining CellComparison Between New Gold Electrolytic Refining Cell and Traditional Electrolytic Refining Cell

1、Current Density: The traditional method operates at a current density of 300 A/m², while our new electrolytic refining method has achieved currents exceeding 1200 A/m².

2、Gold Concentration in Electrolyte: The traditional method has a gold concentration of 350 g/100 mL, whereas the new method reduces this to 100 g/100 mL.

3、Consumption of HCl:In terms of production efficiency and processing duration, the traditional method is relatively inefficient with lengthy processing times and significant evaporative losses of HCl.

The consumption of NaOH in acid gas absorption systems has also been reduced from approximately 10 tons per ton of gold to around 3 tons per ton of gold.

4、Correlation: As a result, the corresponding acid gas absorption system consumes less NaOH, reducing costs and optimizing the overall process efficiency.

-

The Rapid Induction Melting Furnace for Gold

The Rapid Induction Melting Furnace for GoldThe Rapid Induction Melting Furnace for Gold:

This rapid induction melting furnace utilizes electromagnetic induction technology. By generating alternating magnetic fields within the metal, it produces eddies that achieve rapid and uniform heating and melting. This heating method not only has high efficiency but also significantly reduces oxidation and decarburization phenomena, ensuring the purity of gold.

In metallurgical applications, this rapid induction melting furnace exhibits significant advantages. It allows precise control of melting temperatures, ensuring consistency and stability in the gold melting process. Additionally, the furnace features energy-saving characteristics with its efficient energy conversion and low-energy consumption design, making it an ideal choice for the metallurgical industry.

The furnace also boasts a high level of automation, with user-friendly operation that enables fully automatic unmanned operation, further enhancing production efficiency.

-

The High-Efficiency Gold Extraction Method

The High-Efficiency Gold Extraction MethodThe High-Efficiency Gold Extraction Method

Steps:

a. Mineral Grinding

b. Agitation and Pressing Block

c. Roasting

d. Crushing and Mixing

e. Chemical Leaching

f. Press Filtration

g. Electrorefining

Description of the Method:

This method employs solid block-shaped composite gold roasting technology, allowing for multiple recoveries of residual gold from the by-products and wastewaters across various stages of the process. The entire extraction process can be completed on a single production line, achieving high product rates with minimal residual gold left in by-products and waste liquids.

-

Gold Flotation in Oxidized Copper Ores

Gold Flotation in Oxidized Copper OresImproving the Efficiency and Economic Benefits of Gold Flotation in Oxidized Copper Ores

Challenges in Gold Flotation from Oxidized Copper Ores

Oxidized copper ores are one of the most important sources for extracting gold. However, the flotation process for gold in oxidized copper ores faces numerous difficulties. This article will explore the reasons behind the challenges in gold flotation from oxidized copper ores from the following perspectives:

Co-occurrence of Gold with Multiple Minerals: Gold in oxidized copper ores often co-occurs with various other minerals, which differ significantly in their properties. This makes it difficult to achieve effective separation during the flotation process, especially when gold is present as fine particles or encapsulated forms.

Adverse Effects of Gangue Minerals: Gangue minerals such as silicates (silicic acid), carbonates (calcium-based), and oxides (iron-based) in oxidized copper ores negatively impact gold flotation. These gangue minerals reduce the selectivity of flotation reagents, making it difficult to precisely capture gold.

Ineffectiveness of Traditional Flotation Reagents: Conventional flotation reagents often fail to achieve satisfactory results for gold extraction from oxidized copper ores.