-

Low-Grade Gold Mine Soaking Method for Extracting Gold

Low-Grade Gold Mine Soaking Method for Extracting GoldLow-Grade Gold Mine Soaking Method for Extracting Gold:

Preparation of Low-Grade Gold Ore: After removing surface mud, dirt, and other impurities from the low-grade gold ore, crush and screen it to select ores with particle sizes less than 70mm. Mix this with lime in a ratio of 3:1 (ore:lime) and stir uniformly to form a mixture. Form piles with this mixture.

Impregnating Compound : Adjust the pH of the solvent to between 10-12, creating a basic solution. Add cyanide to form the dye solution.

Spraying: Spray the dye solution continuously over the ore piles to produce the pregnant solution.

Gold Adsorption on Activated Carbon: Pump the pregnant solution through activated carbon columns filled with activated charcoal. The gold complexes in the solution are absorbed by the activated carbon, resulting in loaded carbon containing gold and a low-gold content solution (pregnant solution).

Reprocessing Low-Gold Solution: Recycle the low-gold content solution by repeating steps 2, 3, and 4.

Refining Raw Gold: Process the loaded carbon from step 4 to obtain raw gold.

-

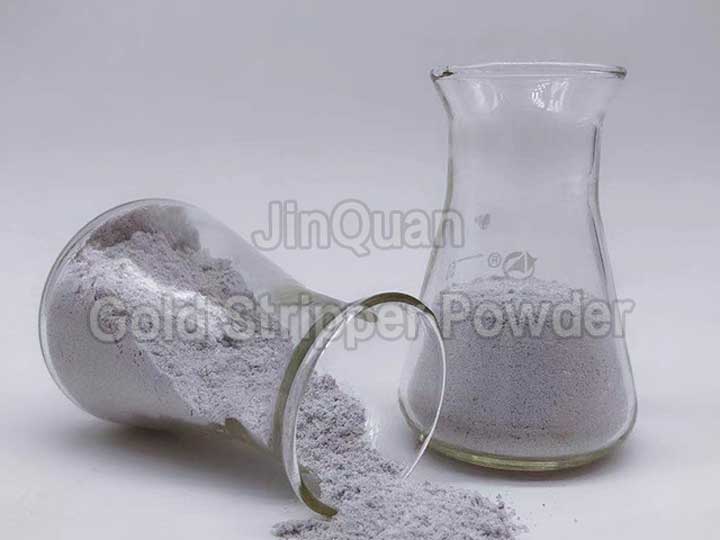

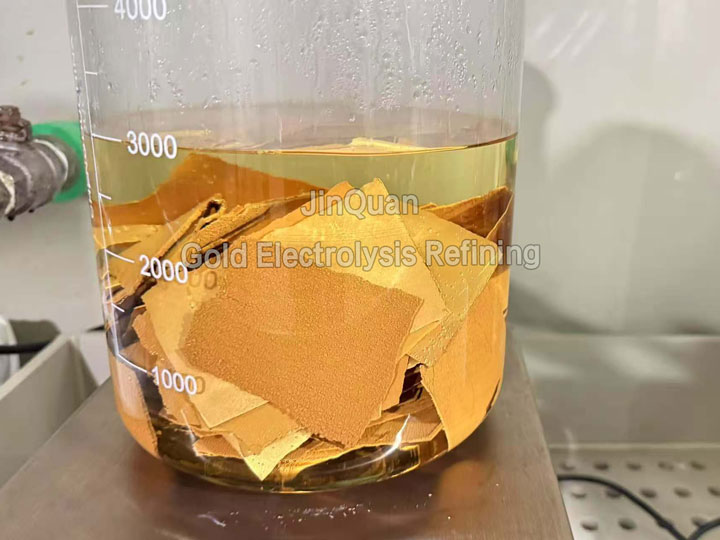

Gold Stripper Powder And Gold Recycling Process

Gold Stripper Powder And Gold Recycling ProcessHigh-Efficiency and Environmental gold stripper powder and Gold Recycling Process

gold stripper powder includes: gold mining agents, anti-staining salt (S), and surfactants.

Gold Recycling Process: Includes:Preparation of Desorption Solution、Electroplating with Zinc Wire、Removal of Lead。

Environmental and Non-Toxic Advantages: The desorption powder and gold recycling process outperforms traditional methods in terms of:Significant improvement in gold recovery rate.Enhanced purity of recovered gold.

-

Method for Extracting Gold from Gold Tailings

Method for Extracting Gold from Gold TailingsMethod for Extracting Gold from Gold Tailings:

1、Creating Slurry: Mix gold tailings with water to form slurry.

2、Fine Processing: Process the slurry through fine processing to reduce particle size below 2 micrometers. Additionally, a chemical agent containing a ligand capable of forming complexes with gold ions is added either during or prior to the fine processing. After fine processing, the chemical agent is thoroughly reacted with the slurry.

3、Solid-Liquid Separation: Perform solid-liquid separation to isolate the liquid phase, which contains gold complex ions.

This method operates under mild conditions and has low production costs. It consumes less reagent, achieves high extraction speed, and a recovery rate of up to 98%. Post-extraction, the solid residue can be utilized for manufacturing ceramic tiles, concrete additives, lightweight void fillers, or dried as filling material for rubber or plastic. This process effectively converts waste into valuable resources through maximum resource utilization.

-

Gold Mining Beneficiation Processing

Gold Mining Beneficiation ProcessingGold Mining Beneficiation processing

1、Heavy Mineral Separation: Heavy mineral separation is one of the oldest and most widely applied methods in gold mining. It is considered the most effective, economical, and primary method for alluvial gold mines.

2、Flotation Method: The flotation method is based on the differences in physical and chemical properties of minerals. After treating with flotation reagents, valuable minerals are selectively attached to air bubbles, achieving separation through this process.

3、Chemical Leaching and Roasting Process: This method utilizes chemical or physical-chemical principles to separate and recover precious components from ores or concentrates based on the chemical differences between gangue and ore minerals.

4、Piling Leaching Production Process: The piling leaching production process is characterized by its simplicity, ease of operation, low investment costs, and high efficiency. Due to these advantages, this method has seen rapid development in industrial applications.

-

Gold Mining Technology

Gold Mining TechnologyGold Mining Technology:

Overview of Gold Mining: Gold content in ores is extremely low, requiring the breaking and grinding of ore stones followed by mineral separation methods to either preliminary concentrate or extract gold from the ore.

Commonly Used Methods in Gold Mining: The most commonly used methods are heavy mineral separation (henceforth referred to as "heavy selection") and flotation (flotation method).

Significance of Heavy Selection in Alluvial Gold Production: In alluvial gold production, heavy selection plays a crucial role.

Flotation Method Widely Applied in Hard Rock Mines: The flotation method is widely employed in hard rock mines, with approximately 80% of rock gold mines in China using this method to extract gold.

Improvements in Mining Technology and Equipment: The level and equipment standards of mineral separation technology have significantly advanced.

-

Extraction Of Gold From Cyanide Waste Solutions

Extraction Of Gold From Cyanide Waste SolutionsGold Recovery from Cyanide Waste Solutions:

The treatment method involves recovering gold from cyanide waste solutions, primarily generated by electronics manufacturing facilities that contain gold. This process utilizes either ferrous chloride (FeCl2) or ferrous sulfate (FeSO4) as a reducing agent to extract gold from the solution.

Pre-Treatment Process:

The cyanide waste solution is heated until it becomes viscous.

Hydrochloric acid (HCl) is then added, repeating this process 2~3 times.

After dilution with water and reheating to a temperature of 70-80°C, a reducing agent (iron(II) salts) is slowly introduced until all the gold is precipitated.

Alternative Reduction Method:

Sodium thiosulfate (Na2S2O3) or sulfur dioxide (SO2) can also be employed as reducing agents to facilitate gold recovery from the cyanide solution.

This method ensures efficient and effective extraction of gold from cyanide waste solutions, adhering to environmental regulations and optimizing resource recovery processes.

-

Gold Recovery From Gold–Cyanide Solutions

Gold Recovery From Gold–Cyanide SolutionsThe process involves treating gold cyanide solution using a PH adjustment method to recover gold.

PH Adjustment Method for Gold Recovery: The [Au(I)(NH3)2(SO3)2]^3- complex ion is stable at a PH of 8~9, making it suitable for electroplating purposes.

Behavior of the Complex Ion Upon pH Reduction: When the pH decreases, the complex ion dissociates into gold ions, sulfite ions, and ammonia (NH3).

Role of Sulfate Ions in Gold Ion Reduction: The sulfate ions reduce the gold ions to metallic gold.

Gold Recovery at Adjusted pH Levels: By adjusting the PH to 2~3 using hydrochloric acid, the gold is reduced to elemental gold powder.

Filtering and Washing for Gold Recovery: After reduction, the gold powder is filtered and washed before being collected for reuse.

-

Treating Silver Waste Gas from Nitric Acid Solution

Treating Silver Waste Gas from Nitric Acid SolutionTechnology for Treating Silver Waste Gas from Nitric Acid Solution:

The concentration of nitrogen oxide waste gas generated from silver electrolysis solution reaches 20,000 to 50,000 mg/m³. The national emission standard is 240 mg/m³. Many places have adjusted their emission standards to 100 mg/m³.

-

Technology for Recycling Silver-Containing Catalyst

Technology for Recycling Silver-Containing CatalystTechnology for Recycling Silver-Containing Catalyst:

Silver Electrowinning Process: This process is used to recover silver from silver-containing catalyst sludge in the chemical and pharmaceutical industries, as well as from silver-containing solutions in the solar energy industry. Since these materials contain silver without significant other metal impurities, we developed a new recycling process.

Process Description:

After leaching with nitric acid, adjust the pH and silver ion concentration of the leaching solution.

Transfer the adjusted solution directly to the silver electrowinning cell for processing.

The depleted solution after electrowinning can be used as makeup water when diluting the leaching solution for the next batch.

The resulting silver powder meets the national standard 1# silver specifications.

Advantages of the Silver Electrowinning Process:

Simple process with low production costs.

Current Applications:

This technology has been applied in Xian Nobi Rare Metal Material Co., Ltd.

Heraeus Technologies (China) Co., Ltd.