Solid-Liquid-Solid Wetting Furnace Process for Dissolution of Chalcopyrite or Concentrate:

The process operates under conditions of over-saturation with water and/or non-hydrated salts. It intentionally and repeatedly applies wetting and drying steps to enhance chemical and physical phenomena on or in the mineral or concentrate, thereby inducing copper crystallization, re-crystallization, and liberation during the non-redox decomposition of sulfides and their subsequent reaction with chlorides.

This method comprises three steps: (a) Wetting, (b) Drying and Over-saturation, and (c) Cleaning and Re-wetting. These steps are performed under temperatures in the range of 20-40°C without considering redox potentials, while minimizing water and acid consumption, with no need for oxygen addition.

The process minimizes water and acid usage because sulfide transformation can occur solely in the presence of hydrated salts or with a small amount of added acid and water. Additionally, it allows reduced water use during agglomeration and/or solidification steps because water molecules from the hydrated salt wet the mineral, minimizing the amount of water required to be added during wetting and agglomeration/solidification.

This method can also be applied to sulfides of less noble metals such as nickel, zinc, cobalt, lead, and molybdenum, regardless of whether arsenic is present in the sulfide mineral matrix.

+8613303827570

+8613303827570

-

gold recovery equipmentgold recovery equipment

gold recovery equipmentgold recovery equipmentDetails of gold recovery equipment

1. Function introduction: The electrolytic gold extraction machine is a technology for wet refining and purification of metals. It can selectively electrolyze valuable metals and is especially suitable for the selective electrolysis (electrolysis) of low-content solutions and solutions with complex components in the metallurgical industry. (accumulation) separation and purification, as well as the recovery of heavy metal ions in wastewater.

2. Technical advantages of gold ecovery equipment:

1)It has the ability to process low-concentration metal solutions, and has higher production efficiency than traditional electrolysis technology to enrich valuable metals in a wider range, from a few tenths of a gram/liter to a few hundred grams/liter of metal concentration for electrolytic production and metal The ability to separate. In particular, it has unparalleled technical advantages in copper-nickel separation and copper-silver separation;

2) It has stronger adaptability to pollutants in the solution and can extract high-purity metals from solutions containing impurities;

3)It has the ability to extract a variety of metals and has the ability to selectively electrolyze metals, and can produce different forms of cathode products (sheets or metal powders) according to the concentration of the solution;

4) The equipment is modular and easy to operate.

-

gold recovery machinesilver/gold recovery machine,silver/gold refining equipment,silver/gold refining equipment

gold recovery machinesilver/gold recovery machine,silver/gold refining equipment,silver/gold refining equipmentInstruction Of Gold Recovery Machine:

The new version gold recovery machine an intelligent touch screen, low-voltage extraction technology, supports fully automated intelligent operation, and offers automatic/manual mode.

The JQ series uses electrolysis to adsorb gold, silver, copper, and other precious metal ions from solutions onto the cathode. Once a certain weight is adsorbed, the precious metal sheets (gold, silver, copper, etc.) are stripped from the cathode. This equipment enables safe and efficient refining and recovery of various solutions containing gold, silver, or copper, ultimately converting the ions in the solution into pure precious metal form.

Product Advantages:

1、High-efficiency recovery of gold, silver, copper, and other valuable metals;

2、Precious metal purity ≥ 99%, with an ion recovery rate ≥ 99%;

3、Low-voltage extraction, highly efficient, and odor-free.

Model Specifications:

Model

JQ-DJC-L3

Product Name

Gold Recovery Machine

Dimensions

43 x 29 x 58 cm

Rated Voltage

220 V

Power

120 w/h

Weight

45 kg

Capacity

18 L~oo

-

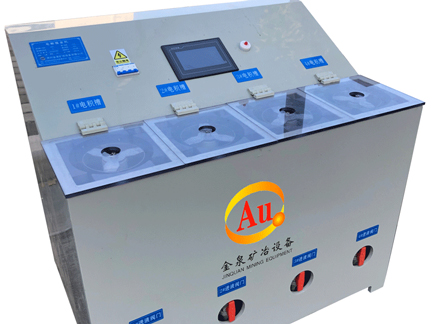

gold extraction machinegold extraction machine,gold recovery equipment

gold extraction machinegold extraction machine,gold recovery equipmentProduct Introduction of Gold Extraction Machine:

Swirl electrowinning is a wet metallurgical technology used for the selective electrowinning and extraction of gold. It is particularly suitable for the selective electrolytic separation and purification of valuable metals from low-concentration or complex-composition solutions in the metallurgical industry, as well as for the recovery of gold from wastewater.

Advantages of Gold Extraction Machine:

1)、Capable of processing low-concentration metal solutions with higher production efficiency compared to traditional electrolytic technologies. It can enrich valuable metals across a wide range of concentrations, from fractions of a gram per liter to hundreds of grams per liter, especially excelling in copper-nickel and copper-silver separation.

2)、Strong adaptability to pollutants in solutions, enabling the extraction of high-purity gold from impure solutions.

3)、Capable of extracting multiple metals with selective electrolysis, and able to produce cathode products in different forms (plates or metal powders) depending on solution concentration.

4)、Modular equipment design with simple operation.

Model parameters of gold extraction machine

Product model

Product Name

Dimensions(mm)

Rated Voltage

Power

Weight(kg)

JQ-DJC-L1

gold extraction machine

450*300*600

220V

300w/h

45kg

JQ-DJC-L3

gold extraction machine

900*1010*800

380V

1500w/h

125kg

JQ-DJC-L4

gold extraction machine

1220*1010*800

380V

2.5kw/h

150kg

JQ-DJC-L5

gold extraction machine

1520*1010*800

380V

3kw/h

180kg

Current: Single tank designed for 100A, voltage 5V.

Each small tank can process approximately 200L of solution. Single or multiple tanks can be selected based on production requirements, with processing speed varying according to concentration.Result of Gold Extraction Machine: